توضیحات

ABSTRACT

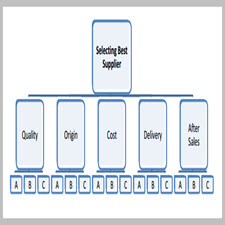

Supplier selection is one of the most important functions of a purchasing department. Since by deciding the best supplier, companies can save material costs and increase competitive advantage. However this decision becomes complicated in case of multiple suppliers, multiple conflicting criteria, and imprecise parameters. In addition the uncertainty and vagueness of the experts’ opinion is the prominent characteristic of the problem. Therefore an extensively used multi criteria decision making tool Fuzzy AHP can be utilized as an approach for supplier selection problem. This paper reveals the application of Fuzzy AHP in a gear motor company determining the best supplier with respect to selected criteria. The contribution of this study is not only the application of the Fuzzy AHP methodology for supplier selection problem, but also releasing a comprehensive literature review of multi criteria decision making problems. In addition by stating the steps of Fuzzy AHP clearly and numerically, this study can be a guide of the methodology to be implemented to other multiple criteria decision making problems.

INTRODUCTION

Supplier selection, which includes multi criteria and multiple conflicting objectives, can be defined as the process of finding the right suppliers with the right quality at the right price, at the right time, and in the right quantities. It is noted that, manufacturers spend more than 60% of its total sales on purchased items [1]. In addition, their purchases of goods and services constitute up to 70% of product cost [2]. Therefore, selecting the right supplier significantly reduces purchasing costs, improves competitiveness in the market and enhances end user satisfaction [3]. Since this selection process mainly involves the evaluation of different criteria and various supplier attributes, it can be considered as a multiple criteria decision making (MCDM) problem [4]. Based on several criteria and alternatives to be considered, various decision making methods have been proposed to provide a solution to this problem [5]. Basically there are two types of supplier selection problems [6]. In single sourcing type, one supplier can satisfy all the buyer‟s needs. In the multiple sourcing type, no supplier can satisfy all the buyer‟s requirements. Hence the management wants to split order quantities among different suppliers [7]. As a pioneer in the supplier selection problem, Dickson [8] identified 23 different criteria for selecting suppliers, including quality, delivery, performance history, warranties, price, technical capability, and financial position [9]. With a thorough literature survey, Weber, et al. [10] reviewed 74 different articles by classifying into three categories; linear weighting methods, mathematical programming models, and statistical approaches. Following Weber et al. [10], De Boer et al. [11], identified four stages for supplier selection including; definition of the problem, formulation of criteria, qualification, and final selection respectively [12]. According to one of the recent classifications made by Sanayei et al. [13], there are six classes. These are multi attribute decision making techniques (Analytic Hierarchy Process- AHP, Analytic Network Process- ANP, Technique for Order Preference by Similarity to Ideal SolutionTOPSIS), mathematical programming (Linear Programming- LP, Goal Programming- GP or Mixed Integer Programming- MIP), probabilistic approaches, intelligent approaches (neural networks, expert systems), hybrid approaches (AHP-LP, ANP-MIP) and others.

Year: 2013

Publisher : IJMVSC

By : Mustafa Batuhan AYHAN

File Information: English Language/ 13 Page / size: 625 KB

Download: click

سال : 2013

ناشر : IJMVSC

کاری از : Mustafa Batuhan AYHAN

اطلاعات فایل : زبان انگلیسی / 13 صفحه / حجم : KB 625

لینک دانلود : روی همین لینک کلیک کنید

نقد و بررسیها

هنوز بررسیای ثبت نشده است.